Custom solutions

Stamping and tube form products which meet your requirements. In addition to our extensive selection of standard products, we specialize in custom development. Here are some examples:

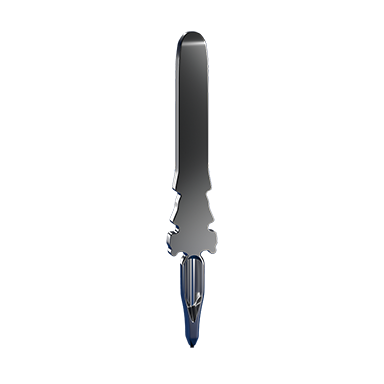

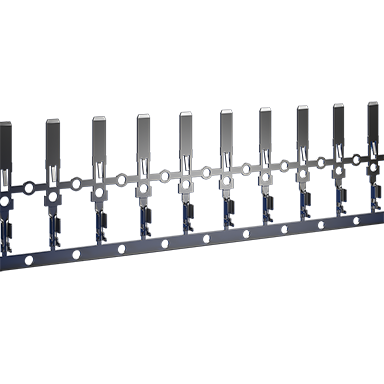

Stamping

Product variety, flexibility and effective production of large series.

Grounding contacts

Spring contact made of a special minimal stress relaxation Cu alloy for use on metal rail conductors.

Press fit terminals

For high current applications; mounted using solderless insertion into specially designed printed circuit boards.

Reeled components

Designed for easy processing and low automation costs.

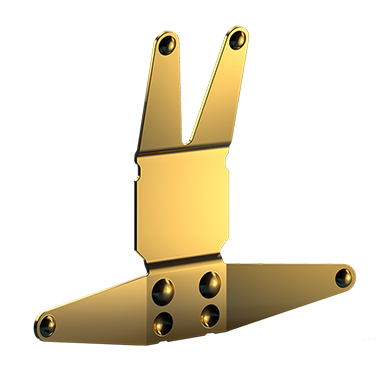

Spring contacts

Made with high-strength gold-plated spring steel

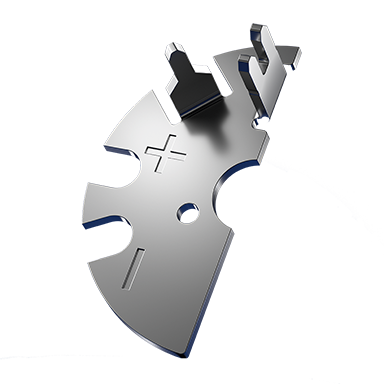

Contact plates

With formed soldering tabs and embossed marking.

Round Contacts

Manufactured with circumferential spring elements utilizing a special maximum strength Cu alloy.

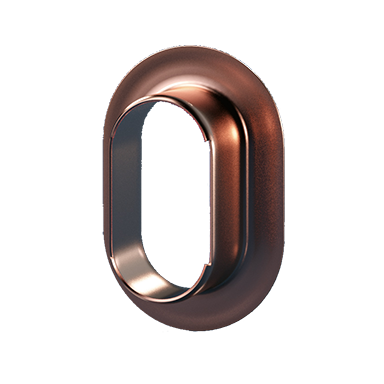

Oval bushings

For insertion into plastic components designed to tolerate the required forces.Tube form products

Tube form products in a wide variety of shapes from all formable metals.

Tubular rivets

The classic product as per DIN 7340.

Seamless base pin

For electrical or mechanical connection of wires and PCBs.

Tube formed products

Economical alternative product to replace turned parts.

Sealing sleeve

As socket or shielding of electronic components and sensors.Stamping

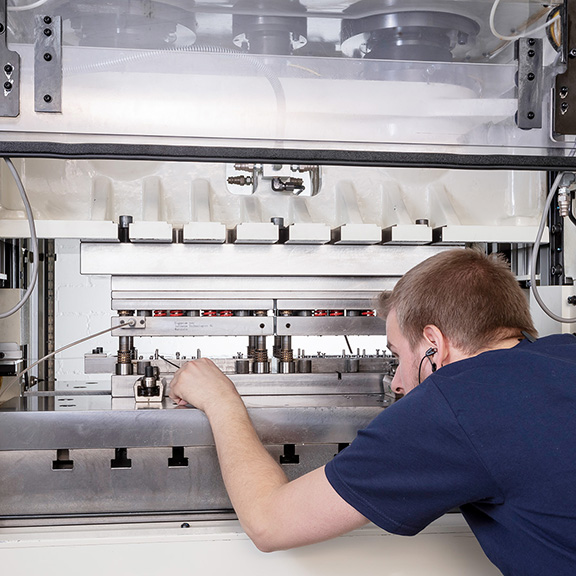

With 40 automatic presses (200 to 900 kN), our broad range stamping department provides the foundation for wide reaching product variety, flexibility and effective volume manufacturing. Precision stamped products can be supplied in material thicknesses of 0.1 to 1.5 mm.

In-house toolmaking, high-performance presses with process monitoring and much more – Osterrath is ready to meet your needs.

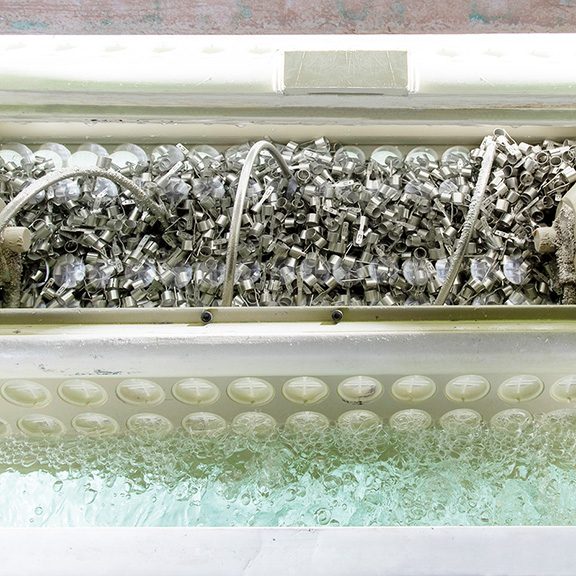

Tube form products

We produce tube form products in various shapes from all deformable metals from 0.8 mm to 42 mm in diameter.

Pipe rivets, support sleeves, collar sleeves, plug pins, double collar sleeves, end sleeves or replacement of turned parts – any inquiry is welcome.

Custom solutions

The perfect solution for your requirements may not be available right off the shelf. We specialize in providing you with expert advice that goes far beyond material delivery.

Expert advice

Our engineers and technicians are available to assist you in the development of your specific products.

Development

Our investment in FEM simulation software gives you the opportunity to optimize the development process.

Prototypes

Building prototypes, even of complex parts, allows an assessment of the product’s technical properties well before investment in the actual tool.

Tool Design

Tools are designed using the most advanced industry-specific expert software.

Tool and die making

Our state-of-the-art tooling shop has all the capabilities to produce the best performing progressive dies.

Manufacturing

Approximately 40 presses with closing forces between 200 and 900 kN and up to 1100 mm table lengths offer the most flexible manufacturing options.

Plating / coating

Working together with external partners, our in-house electroplating capability gives us the potential to provide any technically conceivable coating.

Quality Management

An ISO 9001:2015 (PDF) integrated quality management system secures our processes. Any additional requirements, e.g. automotive market demands, are implemented project-related.

From idea to the delivery of a final product solution

You provide the idea and we quickly develop a practical solution which we are happy to review on site with you in person. Together, we then develop the final product concept, which can either be produced as a prototype or moved directly into volume production. We accompany you during product validation and provide comprehensive service during the entire lifetime of the product.

In-house tool and die making

Our state-of-the-art toolmaking capability enables a complete range of functions to enable maximum performance from our progressive dies.

Prototyping

By using several high-precision laser systems, we are able to supply realistic prototypes at short notice

Professional expert advice

Now you have a picture of how we all work together at Osterrath. Give us a call... the opportunity to help you is welcome. We look forward to hearing your ideas and we will respond quickly – that is our promise.

— Contact us!